Why Tanker Trucks Have Chains Hanging from the Back

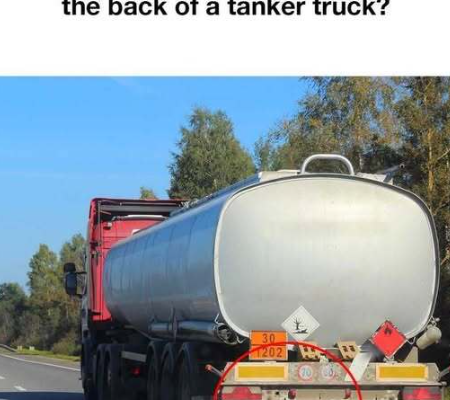

If you’ve ever driven behind a fuel tanker truck, you may have noticed something curious: chains dragging along the road behind it. At first glance, they might seem like a strange leftover from the truck’s construction or some sort of loose equipment. In reality, those chains serve a crucial safety function that can literally prevent catastrophic accidents.

This seemingly simple piece of hardware is part of a broader system designed to combat an invisible, but potentially deadly, hazard: static electricity buildup.

The Hidden Threat: Static Electricity

Whenever a tanker truck transports flammable liquids such as gasoline, diesel, or certain chemicals, the movement of the liquid inside the tank can cause friction. This friction isn’t between the fuel molecules themselves so much as between the liquid and the inner walls of the tank. The result is the generation of static electricity—a charge that builds up over time.

Now, under normal conditions, static electricity is just an everyday nuisance. You’ve probably felt a small shock after walking across a carpet and touching a doorknob. In the confined space of a metal fuel tank containing thousands of liters of highly flammable vapor, however, a sudden spark could have devastating consequences. A single discharge could ignite vapors, leading to an explosion or massive fire.

How Chains Prevent Disaster

The dangling chains on a tanker truck work as a grounding mechanism. They maintain continuous contact with the road surface, allowing any built-up static charge to safely discharge into the ground before it can accumulate to dangerous levels.

The principle here is simple: electricity always seeks the path of least resistance to reach the earth. Without a grounding path, static charges would remain on the truck’s body or tank, waiting for the right moment (or wrong moment, from a safety standpoint) to jump to a nearby conductor—such as a fuel pump nozzle—through a spark.

By dragging a conductive chain along the ground, the truck effectively “bleeds off” the charge in tiny, harmless increments.

Why Chains Instead of Just Tires?

It might seem logical to assume that the truck’s tires, being in contact with the road, would handle grounding. However, modern tires are made with high-resistance rubber compounds designed to insulate rather than conduct electricity. This is a safety measure for vehicles in general—insulating the vehicle from lightning strikes or ground faults—but for tankers, it creates a problem: no natural path for static discharge.

While some tires are made with conductive carbon to reduce static buildup, it’s not reliable enough for transporting flammable materials. A chain provides a direct, consistent grounding link regardless of tire type or road conditions.

The Role of the Chain During Fuel Delivery

When a tanker arrives at a fuel depot or gas station to load or unload, static discharge risk is at its peak. The movement of fuel—flowing at high speed into or out of the tank—generates even more static electricity than when the truck is simply driving.

At this point, safety protocols kick in:

-

Grounding Cables – Workers connect the tanker to a dedicated grounding system at the site before starting any fuel transfer. This ensures the tanker is at the same electrical potential as the ground, preventing sparks.

-

Bonding – The delivery hose is bonded to both the tanker and the receiving storage tank. This ensures there’s no potential difference between the two, which could otherwise cause a spark when connecting or disconnecting the hose.

The chains are the first line of defense, bleeding off static while the truck is moving, so that by the time it arrives for delivery, there’s already a lower charge risk.

Material and Design of the Chains

The chains used for grounding are usually made from steel, which is an excellent conductor. They are attached in a way that allows them to hang low enough to maintain constant road contact, but not so low that they create excessive drag or get snagged.

The design often includes multiple chain links in contact with the ground to ensure redundancy—if one link breaks or is lifted off the ground temporarily, another maintains contact. Over time, the ends of these chains can become worn or frayed from constant abrasion, which is why they are inspected regularly as part of a tanker’s safety maintenance.

Beyond Fuel: Other Uses of Grounding Chains

Although fuel tankers are the most visible example, grounding chains are also used on trucks transporting other flammable or volatile cargo, such as:

-

Liquid propane or butane

-

Industrial chemicals like ethanol or acetone

-

Powdered materials that can produce combustible dust (e.g., flour, grain, or coal dust)

In each case, the danger is the same: a static discharge could ignite a flammable atmosphere, leading to explosions or fires.

Static Electricity and Weather

Another factor in static buildup is weather. Dry air is a poor conductor of electricity, which means static charges dissipate more slowly. In colder, drier months—or in arid climates—static risks increase, making grounding chains even more important.

Humidity can help reduce static buildup, but it’s not a reliable safeguard. Fuel transport safety regulations don’t take seasonal changes into account; chains are mandatory year-round in most jurisdictions.

Regulations and Safety Standards

Grounding requirements for tanker trucks are enforced by national and international safety agencies. In the United States, the Department of Transportation (DOT) and the National Fire Protection Association (NFPA) have guidelines that require anti-static measures for fuel transport vehicles. Similar regulations exist in the European Union, Australia, and other countries.

These rules don’t specify chains as the only acceptable method of static discharge—other systems like conductive grounding straps or integrated discharge plates can be used—but chains remain popular due to their simplicity, low cost, and proven effectiveness.

Common Misconceptions

There are a few misconceptions about these chains:

-

“They’re just for reducing noise or vibration.” While the clinking sound might be noticeable, noise reduction isn’t their purpose. They are installed specifically for safety.

-

“They help with braking or traction.” The chains have nothing to do with the vehicle’s braking performance.

-

“They’re lightning protection.” While grounding chains may help dissipate small charges, they are not designed to protect against lightning strikes. Lightning safety relies on the vehicle’s metal body acting as a Faraday cage.

The Cost of Not Using Chains

History offers sobering reminders of why static discharge prevention is non-negotiable. Several fuel depot and tanker accidents over the past century have been traced back to sparks igniting vapors during loading or unloading. In some cases, investigators found inadequate or missing grounding systems.

Even a small lapse—such as a chain worn too short to touch the ground—can be enough to allow a dangerous charge to build. This is why inspections are rigorous and frequent.

Conclusion

Those humble chains dragging behind a tanker truck are far from a cosmetic detail—they’re a quiet guardian against an invisible threat. By providing a constant path for static electricity to escape into the ground, they help prevent sparks that could turn a routine delivery into a catastrophic event.

It’s a reminder that in industries dealing with hazardous materials, safety often comes down to small, simple, but meticulously maintained details. Whether you notice them clinking on the pavement or see the sparks they occasionally throw on a dark road, those chains are a vital part of keeping both the driver and everyone nearby safe.