The Real Purpose of Those Mysterious Lines on Towels – Explained (1000 Words)

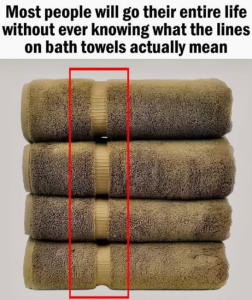

Have you ever unfolded a freshly laundered towel and noticed those subtle yet strangely defined lines or ridges running across it? They don’t seem decorative, and they’re not quite like the ornate borders found on fancier linens. These mysterious towel lines often appear as a band or stripe with a slightly different texture or weave than the rest of the towel. They might not catch your eye immediately, but once you notice them, you start to wonder: what’s the real purpose behind them?

Not Just a Design Choice

At first glance, you might assume these lines are purely decorative—a stylistic flair added by the manufacturer. After all, many towels come in a rainbow of colors and patterns, so why wouldn’t a stripe just be part of the aesthetic?

But the truth runs deeper. While yes, these lines can add a bit of visual interest or make a towel look more refined, they actually serve several practical functions—ones that trace back to the history of textile weaving and modern manufacturing.

1. The Purpose of a Towel Band: Structural Integrity

One of the main functions of the horizontal band or stripe on a towel is to strengthen the fabric and reduce fraying over time. These bands are typically made with a different weave—often tighter or denser—than the rest of the towel, which is designed for maximum absorbency and softness.

When towels are washed repeatedly (and let’s be honest, towels get washed a lot), the edges and seams tend to wear down first. The band acts like a reinforcement zone, holding the loops of fabric together and giving the towel a bit more structural strength where it needs it most. This is especially important for large bath towels that are subjected to twisting, tugging, and constant laundering.

2. A Guide for Folding and Hanging

If you’ve ever worked in hospitality or even just tried to keep your linen closet looking tidy, you’ll recognize the challenge of folding towels uniformly. Those lines provide an unofficial folding guide, especially in hotels and spas.

By aligning the fold along or near the stripe, workers (or meticulous homeowners) can ensure that every towel looks the same on the shelf or rack. This is especially useful for towels stacked in open cabinets or hung on display, as it gives a uniform, polished appearance that’s visually pleasing.

3. Separation of Function: Quick Identification

Sometimes, towels are made with different zones for different tasks. The smooth band isn’t just decorative—it’s less absorbent than the rest of the towel. That might sound like a flaw, but it’s actually intentional.

In industrial or professional settings, that band can act as a non-absorbent area that helps in quickly identifying orientation. For instance, spa or salon professionals might avoid using the banded part to dry or wipe surfaces because it doesn’t absorb water as well. Instead, they go for the fully terry-looped areas.

In your home, you might not consciously think about it, but you may instinctively use the looped part to dry your body and avoid the band, which sometimes feels smoother or less plush. That’s no accident.

4. Durability and Weaving Efficiency

From a manufacturer’s perspective, adding these bands serves another key function: ease of production. Towels are woven on large industrial looms, and adding a simple straight-line pattern with a change in weave provides an efficient way to segment the towel during production without compromising softness or durability.

Moreover, having a flat weave band reduces the number of loops in that area, which makes it easier for embroidering logos or monograms—another win for hotels, gyms, and personalized gift makers. The band is flat, less fluffy, and allows for clean, legible embroidery without disrupting the rest of the towel’s plush texture.

5. Shrink Control

This one is a little lesser known, but some experts in textile manufacturing note that bands help control shrinkage after multiple washes. Since terry cloth towels are made with loops that absorb water, they’re naturally more prone to shrinkage compared to other fabrics.

A tighter-woven band acts almost like a brake, limiting how much the towel can contract in the wash. It helps the towel retain its rectangular shape and prevents it from becoming warped or misshapen after many laundry cycles.

6. A Subtle Luxury Signal

Believe it or not, the presence of those lines may also have evolved as a subtle luxury cue. Higher-end towels often include additional features such as double bands, jacquard weaving, or even satin piping near the stripe. These features signal craftsmanship and attention to detail.

Consumers associate such embellishments with spa-quality or hotel-grade towels, reinforcing the idea that this towel isn’t just utilitarian—it’s indulgent. You’re not just drying off; you’re pampering yourself.

7. A Touch of Tradition

Historically, towels were not mass-produced but handwoven. Weavers used simple variations in stitching and tension to indicate where one section of fabric began and another ended. Those bands are a nod to traditional weaving techniques, and many modern looms have retained that feature simply because it’s become part of what people expect from a “finished” towel.

In fact, if you come across a towel that doesn’t have a band, you might subconsciously feel it’s “unfinished” or less polished—even if the towel is of decent quality. It’s a small, often unnoticed psychological detail, but it matters in product design.

Final Thoughts: More Than Meets the Eye

So, the next time you wrap yourself in a warm towel after a shower or fold a fresh stack of linens, take a moment to appreciate that subtle line. What may have once looked like a purely cosmetic detail is actually a smart, multi-purpose feature with years of engineering, design thinking, and tradition behind it.