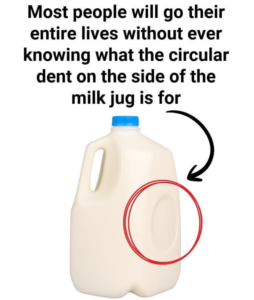

If you’ve ever taken a closer look at a plastic milk jug, you’ve probably noticed a peculiar feature: a large, circular dent or indentation on one of its sides. It’s not a design flaw, nor is it purely decorative—this dent actually serves several important engineering purposes that help keep your milk fresh and safe.

1. Pressure Regulation

The primary reason for the circular dent is to help the jug handle pressure changes. As milk is stored and transported, it undergoes temperature fluctuations. When milk is cold, it contracts slightly. When it warms up, it expands. The dent allows the jug to flex slightly to accommodate these changes in pressure without cracking or bursting. Instead of the rigid plastic breaking, the dent pops outward or inward like a soft cushion, helping the jug remain structurally sound.

This is especially important during transportation. Milk jugs are often moved in large quantities, exposed to heat, cold, and movement. That circular indent acts as a shock absorber, reducing the risk of leakage.

2. Structural Integrity

Milk jugs are typically made from lightweight plastic to reduce production and shipping costs. However, that means they need some smart design to stay strong. The circular dent reinforces the jug’s shape, adding strength to the sides without requiring thicker plastic. This way, manufacturers can keep the jug light and eco-friendly, while still making sure it doesn’t collapse under pressure—literally.

In engineering terms, this is known as “ribbing” or “molding for reinforcement.” The indented shape works like an architectural support beam—it makes the jug more durable while using less material.

3. Impact Resistance

Ever dropped a milk jug and watched it bounce instead of break? That’s partly thanks to the dent. In the event of a drop, the dent can flex outward, absorbing some of the shock from the impact. This helps prevent the plastic from cracking or the cap from popping off. Think of it like a built-in airbag for your milk.

4. Fill Line and Expansion Margin

Sometimes the dent can also act as a visual indicator during the filling process at the dairy facility. It can help machines gauge how full the jug is or offer a space for expansion in case a little extra milk is added. This prevents spillage and ensures the cap can still be securely tightened.

5. Aging and Spoilage Signals (Myth vs. Reality)

There’s a popular rumor that if the dent is “popped out,” it means the milk is spoiled. While it’s true that gas buildup from bacterial growth can cause a jug to bulge, it’s not a reliable spoilage test. Milk can go bad without any visible change to the jug. It’s still best to use the expiration date and the good old-fashioned smell test to check for freshness.

Final Thoughts

So, next time you pour a glass of milk or make your morning cereal, take a second to appreciate that dent on the side of the jug. It’s a small but brilliant bit of design—proof that even the simplest objects can be full of smart thinking. From handling pressure to protecting your fridge from a milky mess, that dent is doing more than meets the eye.